Pergamena History

How did we get here?

Our story begins back in 1550 in Eisenburg, Germany, where members of the Meyer family first took up tanning and leatherwork. Over the centuries, we branched out, working with an expanding range of animal skins. Around 1830, the New World beckoned, and Wilhelm Meyer moved the family business overseas, first to Philadelphia, then to New Jersey in 1856, operating in North Bergen for the next 130 years. During that time, Wilhelm’s grandson incorporated the family business using his own name, Richard E. Meyer & Sons. Finally, in 1981 we relocated to our current home in the Hudson River Valley, in beautiful southern New York.

A Family Legacy

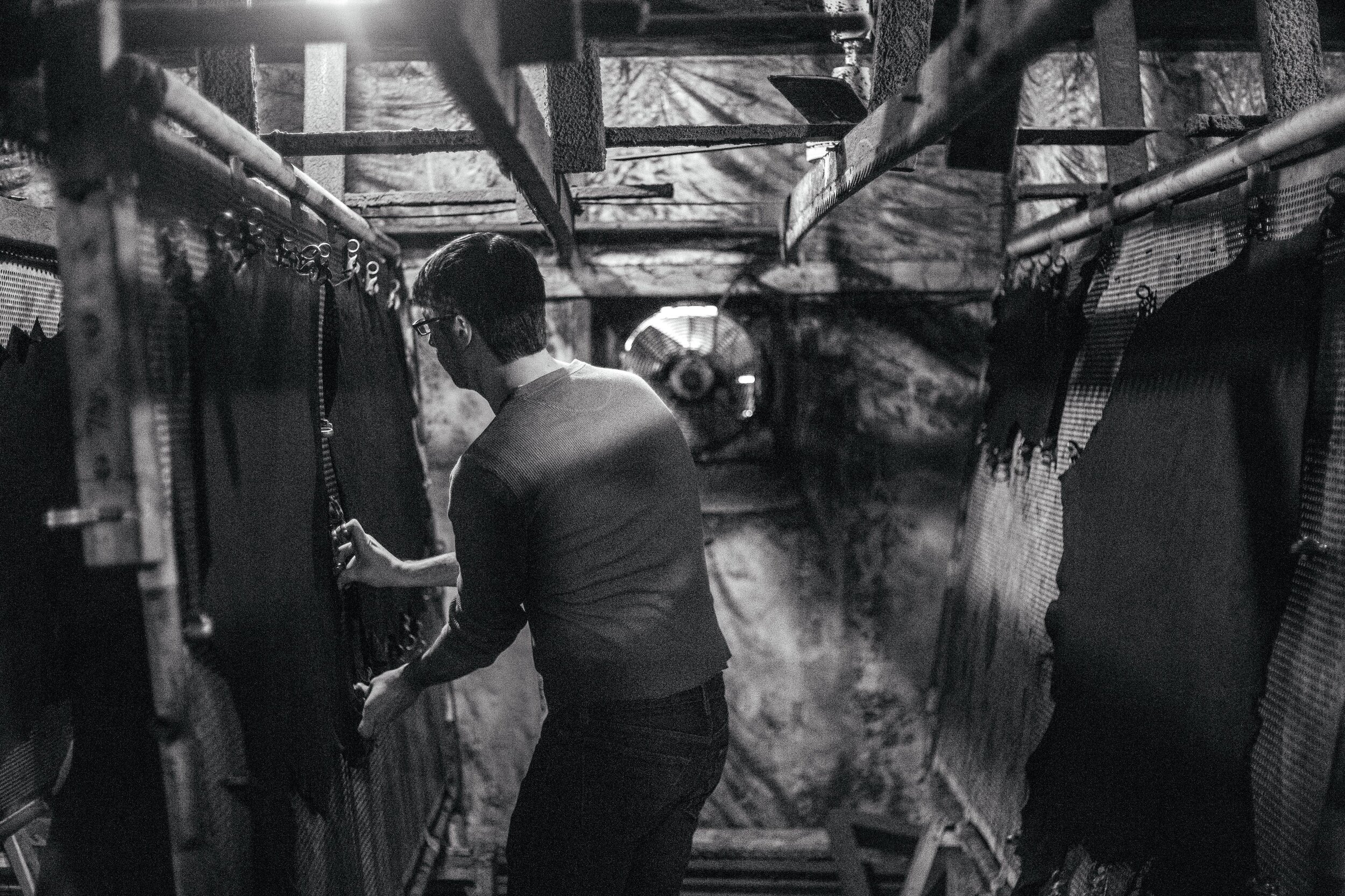

Since 1972, Karl Meyer, the current patriarch, led R.E. Meyer & Sons in the production of fine leathers for a wide range of products including hand-bound books, piano action, shoes, and even lederhosen. In 1999, Karl’s oldest son Jesse developed a new branch of the business and began producing parchment under the name Pergamena. With a background in sculpture, an eye for design, and no fear of getting his hands dirty, Jesse rediscovered and refined the age-old process of hand-making parchment. This new material went hand in hand with the family's leather business, and soon became a driving force in the company's growth. Soon, the company rebranded under the name Pergamena.

As the new brand grew and demand for both parchment and leather increased, the Pergamena family expanded. In late 2008, another son, Stephen, joined the family business. With a deep appreciation for the family tradition and a familiarity with the process due to growing up around the tannery, Stephen has helped bring Pergamena into the modern age and expand into new markets.

Today, after Karl’s retirement, Pergamena is led by Jesse Meyer, CEO. We continue to produce veg-tan quality leather and parchment for dozens of niche industries. With a growing number of employees, an expanded selection of materials, and a drive to continue perfecting our process, we are honored to be able to carry on our family tradition and provide the finest quality leather and parchment to our various customers.

Mission Statement

Using our five centuries of knowledge and our unlimited passion to help creators unlock the potential of parchment and leather. Striving for collective sustainability against an ingrained disposable mindset.

Vision Statement

At Pergamena, we honor our connection to our ancient traditions while still pushing to innovate our products and processes. Using our five centuries of knowledge and our unlimited passion to strive for sustainability and responsible solutions to global problems. We recognize the invisible interdependent web that our industry belongs to, existing attached to both farmers and ranchers as well as artists and designers.

Pergamena treats our products with the same dignity and respect that we extend to our employees and customers. We lovingly handcrafted each skin and hide to bring out and enhance its individual character and beauty. By creating thoughtful and innovative bespoke materials, we set the standard for our customers to create unique and lasting projects.

What is veg-tanning?

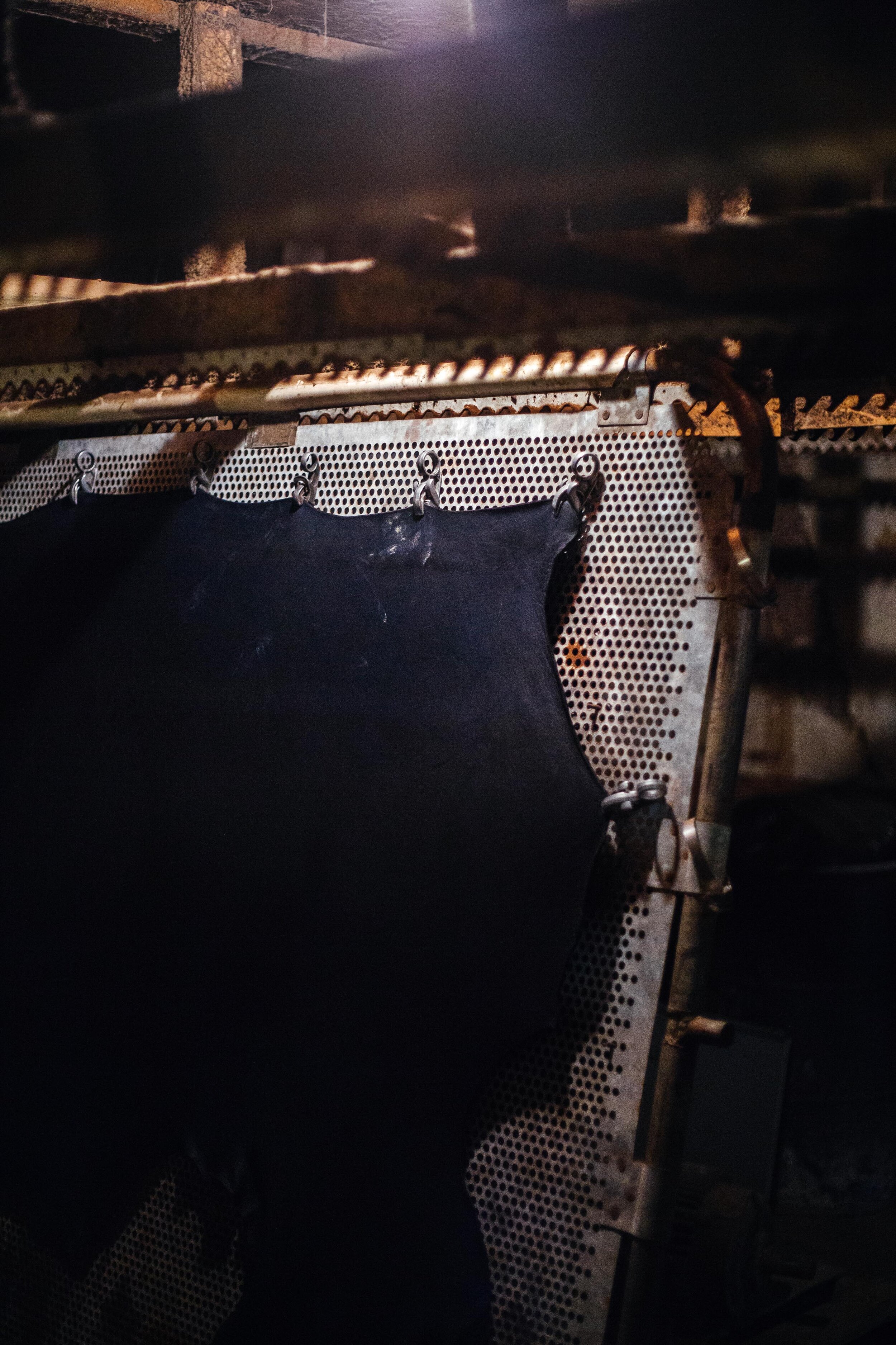

Vegetable tanning, or veg-tanning for short, refers to the type of tannin used in the leather-making process. The two main methods of tanning are chrome-tan and veg-tan. Veg-tanning is the oldest recorded tanning method, using plant derivatives as an all-natural tannin. These tannins are commonly found in tree bark or leaves. The primary tannins used in veg-tanning are sumac, oak, quebracho, hemlock, mimosa, and chestnut. Pergamena exclusively uses a chestnut tannin for our smaller hides because of its archival qualities. However, we use a combination of chestnut and mimosa for our larger hides like cows or buffalo.

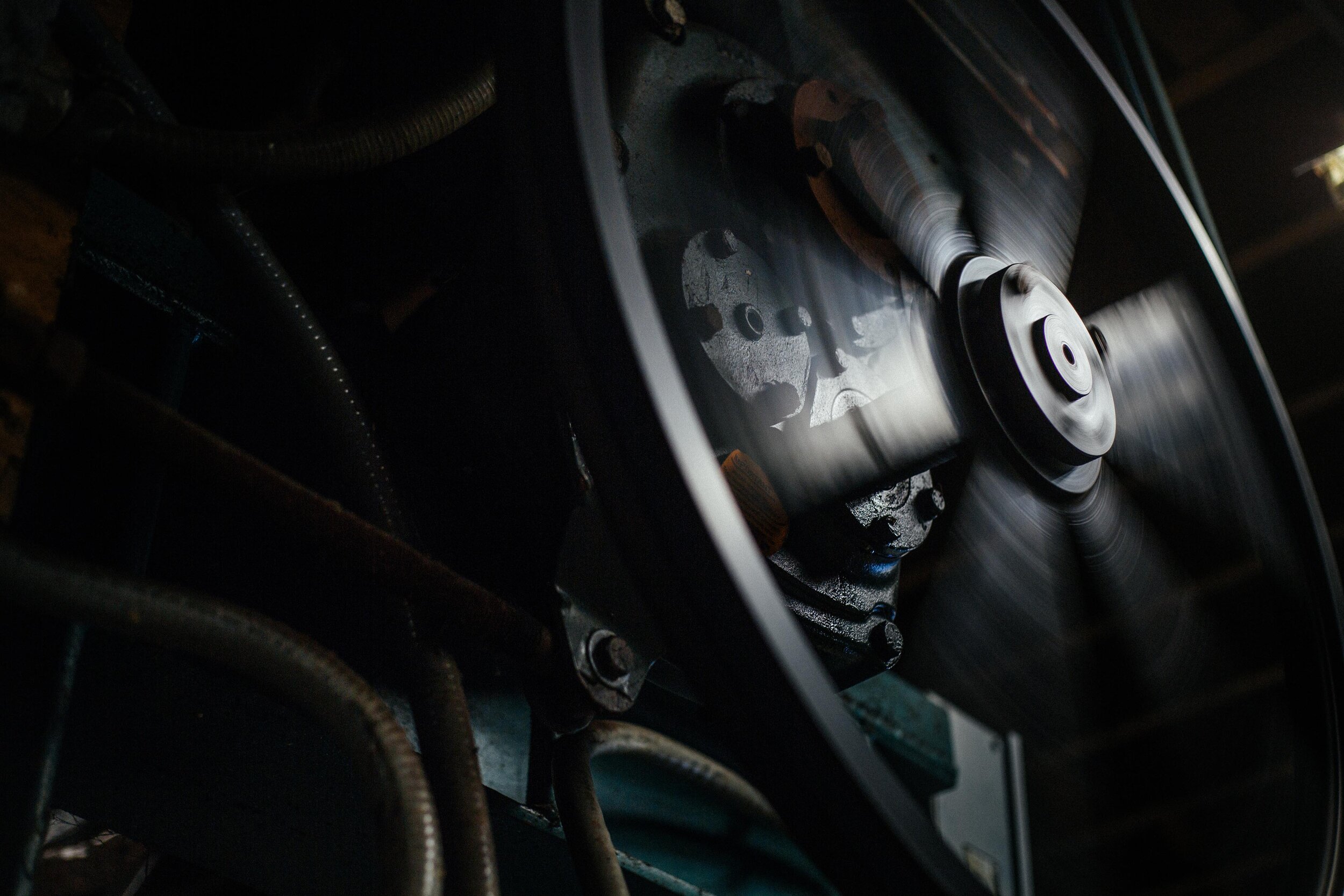

Traditionally the tannins in the plant matter would have been extracted through a long bath-like process that had to be done at specific times of the year. Now thanks to modern technology, commercial tanneries like us use a powder tannin, pictured above.

Why chestnut?

Why did we choose to use primarily chestnut for our process? While there is a very long scientific explanation for this choice, in short, chestnut tanned leather is more archival because of its durability. There are two classifications of vegetable tannins: Pyrogallol and Catechol. Chestnut and oak are pyrogallol tannins, while other tannins like quebracho and hemlock are catechol. Catechol tannins are susceptible to Red Rot. If you have ever handled old leather, especially an old book, and it starts to crumble into a reddish-brown powder, this is red rot. We decided to use Chestnut tannins to meet the archival needs of our conservators, bookbinders, and book artist clients while still providing a veg-tan leather that is as long-lasting and durable as possible for our interiors, furniture, and fashion clients.

Badly degraded leather due to red rot

Photo "Leather red rot 1" by Matthew Fells is licensed under CC BY-NC 2.0.

What makes veg-tan different from chrome-tan?

There are multiple differences between veg and chrome tanned leathers. Primary among them are the environmental impact, tanning process, and inherent leather characteristics.

Chrome-tan, as the name would imply, uses chromium as its tannin. Chromium is a heavy metal and, if not treated carefully, can be very detrimental to the health of the environment and surrounding community. As of 2021, chrome-tanning accounted for about 75% of the leather production in the world. Additionally, most leather production happens in countries with minimal environmental regulations. To read more about this, check out our 2021 industry report blog post.

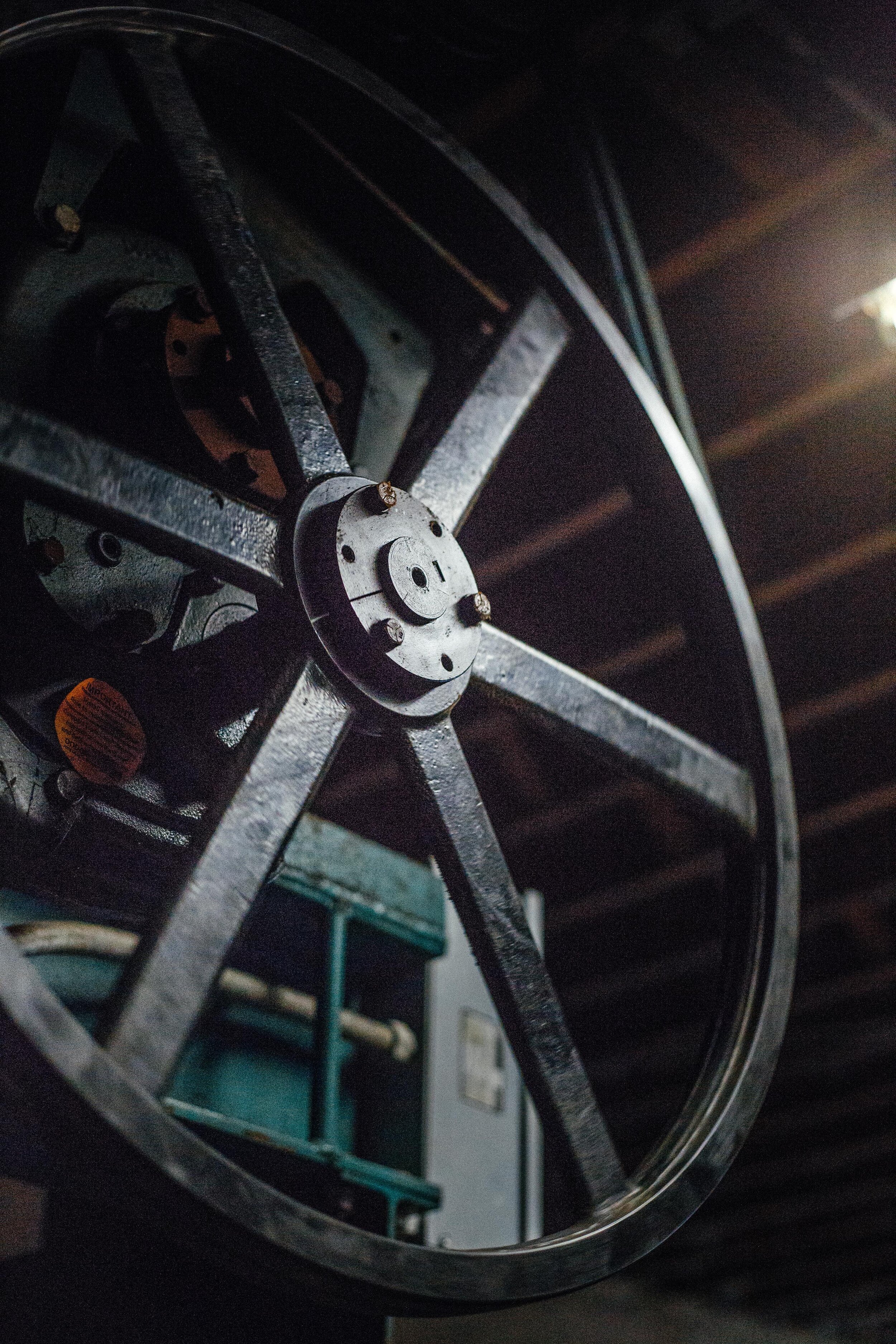

While there are many differences in the chrome vs. veg-tanning process, the main differences are the tannins used and the time required to complete the tanning. Chrome-tanned leather can be completed in a day, whereas veg-tan historically has taken weeks and up to months to complete. With modern technology, our veg-tanning process can be consolidated down to about two weeks.

Finally, there is a big difference in the characteristics of veg-tan and chrome-tanned leather. Both have pros and cons and are best suited for different applications.

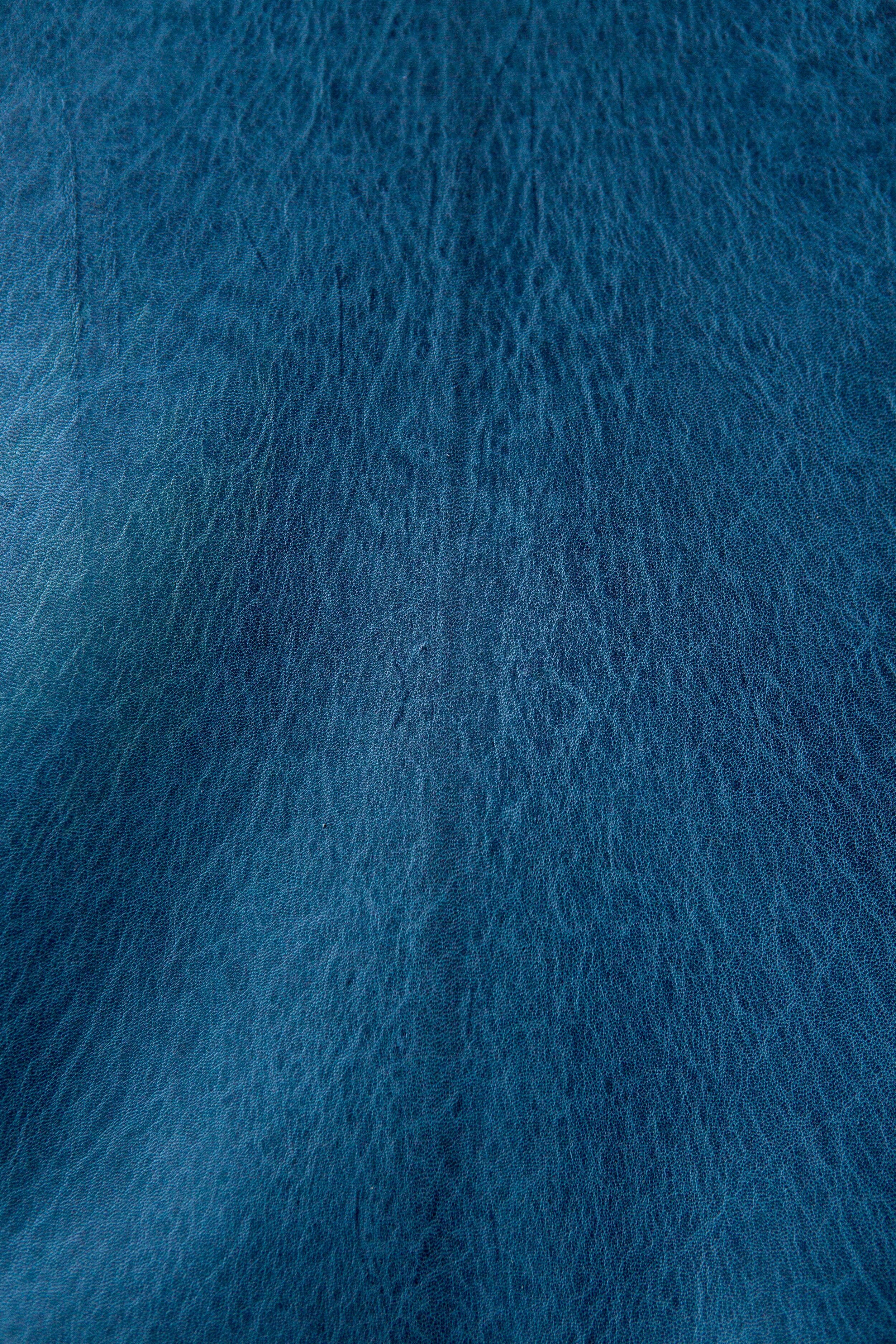

Veg-tanned leather tends to be denser and stiffer, will patina over time, and has that beautiful leather smell we all love. Veg-tan leathers are absorbent, whereas chrome-tan leathers are not. This absorbency means that veg-tan leather will soak up the oils of your hands and patina gracefully over time. It’s this quality; however, that can also be problematic. Unfinished veg-tan leathers will stain easily, and things like rain or spills can permanently change the color of your unfished goods. (We offer both finished and unfinished leather, depending on how adventurous you might be feeling for a project.) Ultimately, veg-tan leathers tend to have more natural character, come in darker, earthy colors, and require more upkeep, but in exchange will age far more richly and wear much better than chrome-tan leathers.

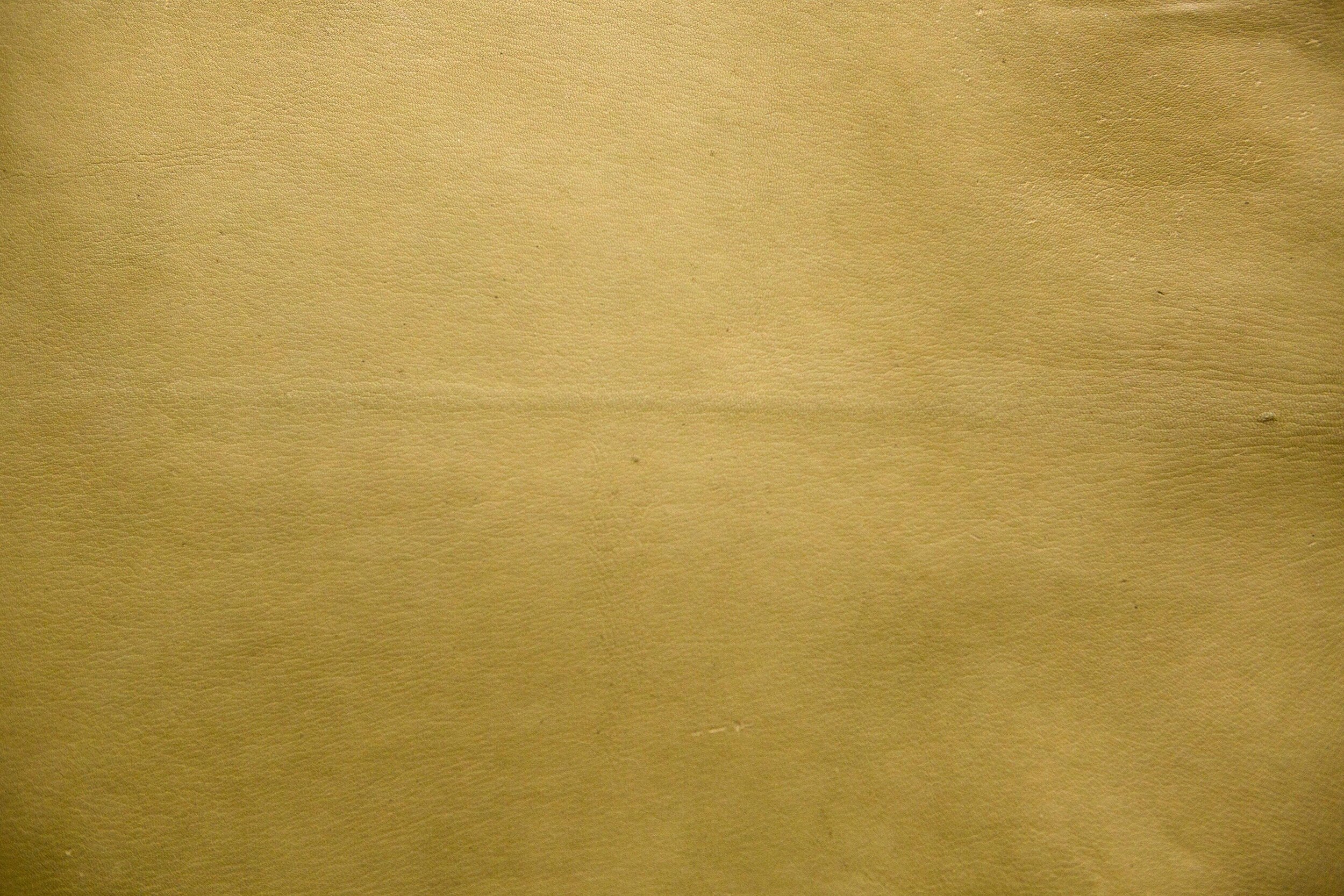

Chrome-tanned leathers are lighter, softer, water resistant, and more uniform. Because of the difference in tanning processes, undyed chrome tan leather is a light blueish grey color, lighter than the cream/khaki color of our undyed veg-tan. This means chrome-tanned leather can be made in bright, vibrant colors. Due to the uniformity, lower cost, lower weight, and availability of chrome-tan, it is the leather of choice for most mass-produced leather goods.

What Sustainability Means To Us

Responsible Production

Pergamena was born as a sustainable company. It’s the key factor that drives our intentions and decisions. Our hides are a waste product of the food industry, saved from the renderer or trash heap. Our leather is and always has been heavy metal-free, and our parchment-making process uses little to no chemical intervention.

Vegetable tanning is a traditional and environmentally sound process, taking approximately 7-14 days to complete. Learn more about Veg-Tan and our process here.

We are committed to a more sustainable future and, as such, continually working towards improving our processes. These improvements include lowering water usage, decreasing our waste, and finding new ways to fit into a regenerative agricultural system.

Through our continued partnerships with phenomenal organizations such as Stone Barns Center and White Oak Pastures, we plan to continue learning, innovating, and serving the needs of our clients and communities. Our hope is that our tan and return and traceable leather programs will continue the legacy of quality and sustainability that our ancestors started over 500 years ago.